Expert Insights: The Latest Trends in Offroad Fabrication

Introduction to Offroad Fabrication

The world of offroad fabrication is constantly evolving, with new trends emerging that shape the way enthusiasts customize and enhance their vehicles. Whether you're a seasoned fabricator or a novice looking to dive into the world of offroad vehicles, staying updated on the latest trends is crucial. This blog post explores some of the most exciting developments in offroad fabrication that are capturing the attention of experts and hobbyists alike.

Innovative Materials

One of the most significant trends in offroad fabrication is the use of innovative materials that offer improved durability and performance. Advanced composites and high-strength alloys are increasingly being used to create lighter and more resilient vehicle components. These materials not only enhance the vehicle's offroad capabilities but also improve fuel efficiency by reducing overall weight.

Carbon fiber, for example, is becoming a popular choice for custom parts like bumpers and fenders due to its lightweight nature and exceptional strength. Similarly, titanium alloys are now being employed in suspension systems to improve performance without compromising on strength.

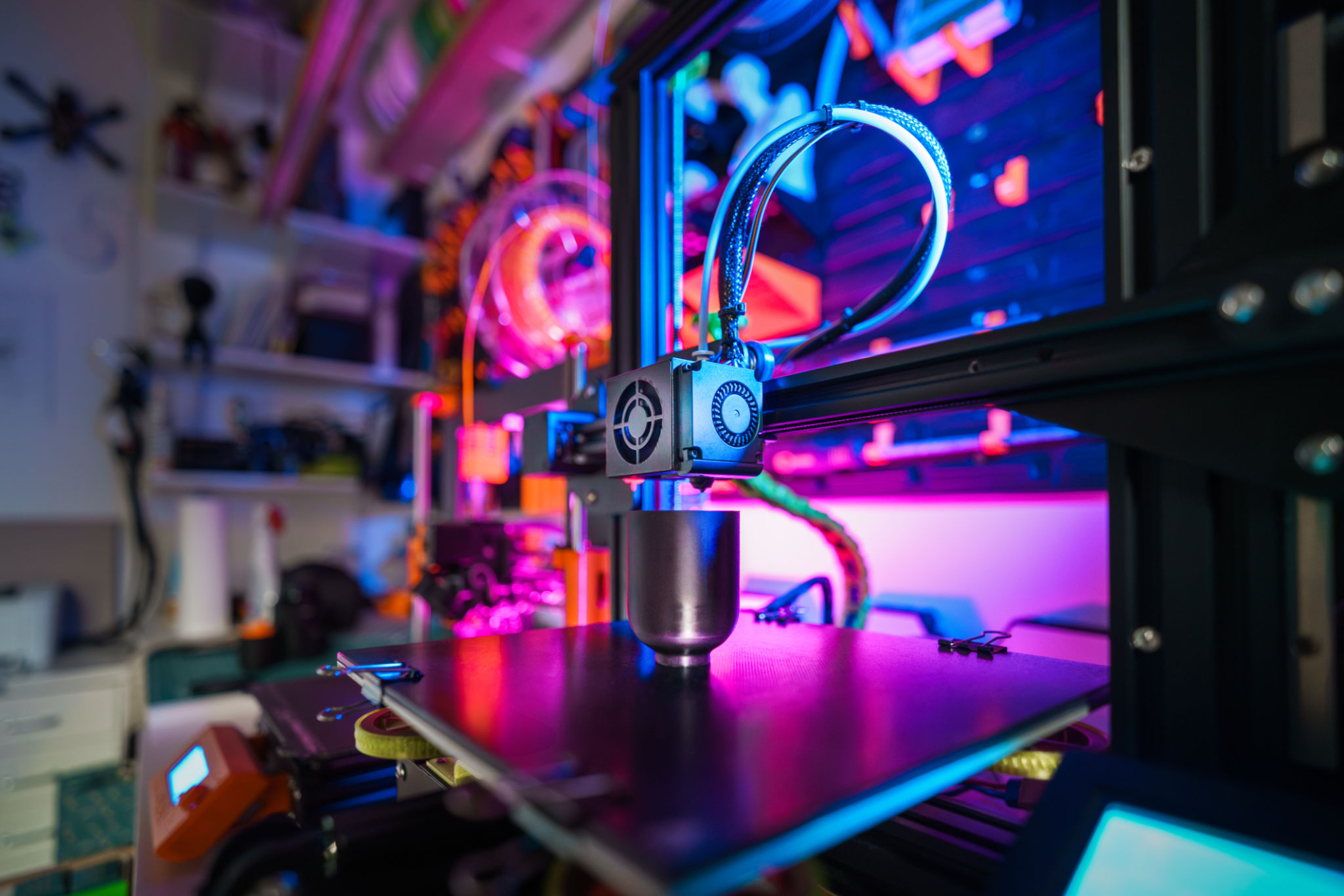

3D Printing Technology

The integration of 3D printing technology in offroad fabrication is revolutionizing the way custom parts are created. This technology allows fabricators to design and produce complex components with precision, reducing lead times and costs associated with traditional manufacturing methods.

With 3D printing, enthusiasts can easily customize their vehicles to suit specific terrains or driving preferences. From bespoke gear shifters to intricate grille designs, the possibilities are endless. This trend is democratizing access to custom fabrication, making it more accessible to a wider audience.

Focus on Sustainability

Sustainability is becoming a key consideration in offroad fabrication as environmental concerns continue to grow. Fabricators are increasingly opting for eco-friendly materials and processes that minimize waste and reduce carbon footprints. Recycled metals and biodegradable composites are gaining traction as viable alternatives to traditional materials.

In addition to material choices, sustainable practices in fabrication also encompass energy-efficient manufacturing processes and the use of renewable energy sources. This shift towards sustainability not only benefits the environment but also aligns with the values of many offroad enthusiasts who are passionate about preserving natural landscapes.

Enhanced Safety Features

As the capabilities of offroad vehicles continue to expand, so does the need for enhanced safety features. Fabricators are incorporating advanced safety technologies into their designs, ensuring that thrill-seekers can enjoy their adventures with peace of mind.

Roll cages, reinforced chassis, and state-of-the-art suspension systems are just a few examples of safety-focused innovations. Additionally, modern offroad vehicles are equipped with sophisticated electronic systems that provide real-time data on vehicle performance and terrain conditions, further enhancing safety and control.

Customization for Personal Expression

Customization remains a central theme in offroad fabrication as enthusiasts seek to express their individuality through their vehicles. From unique paint jobs to personalized accessories, the options for customization are virtually limitless.

This trend is fueled by a growing community of offroad enthusiasts who share their creations on social media platforms, inspiring others to explore their creative potential. The desire for personalization extends beyond aesthetics, with many fabricators offering bespoke solutions tailored to specific driving styles and preferences.

Conclusion

The latest trends in offroad fabrication reflect a dynamic landscape where innovation, sustainability, and personal expression converge. By embracing new materials, technologies, and practices, fabricators are pushing the boundaries of what's possible in the world of offroad vehicles. As these trends continue to evolve, they promise exciting opportunities for both seasoned professionals and newcomers eager to make their mark on this thrilling hobby.