DIY Tips for Maintaining Your Custom Rock Crawler

Regular Inspection and Cleaning

Maintaining your custom rock crawler involves regular inspection and cleaning. Begin by checking for any visible damage or wear on the suspension, tires, and undercarriage. Look for cracks, dents, or any other signs of potential problems. Cleaning your rock crawler is equally important. Remove accumulated dirt, mud, and debris to prevent rust and corrosion. A pressure washer can be a handy tool for this task, but ensure you don't damage sensitive components.

Fluids and Lubrication

Proper lubrication is crucial for the smooth operation of your rock crawler. Regularly check the levels of essential fluids such as engine oil, transmission fluid, brake fluid, and coolant. If any fluid levels are low, top them up and check for leaks. Lubricate joints, axles, and other moving parts to reduce friction and wear. Using high-quality lubricants will enhance performance and longevity.

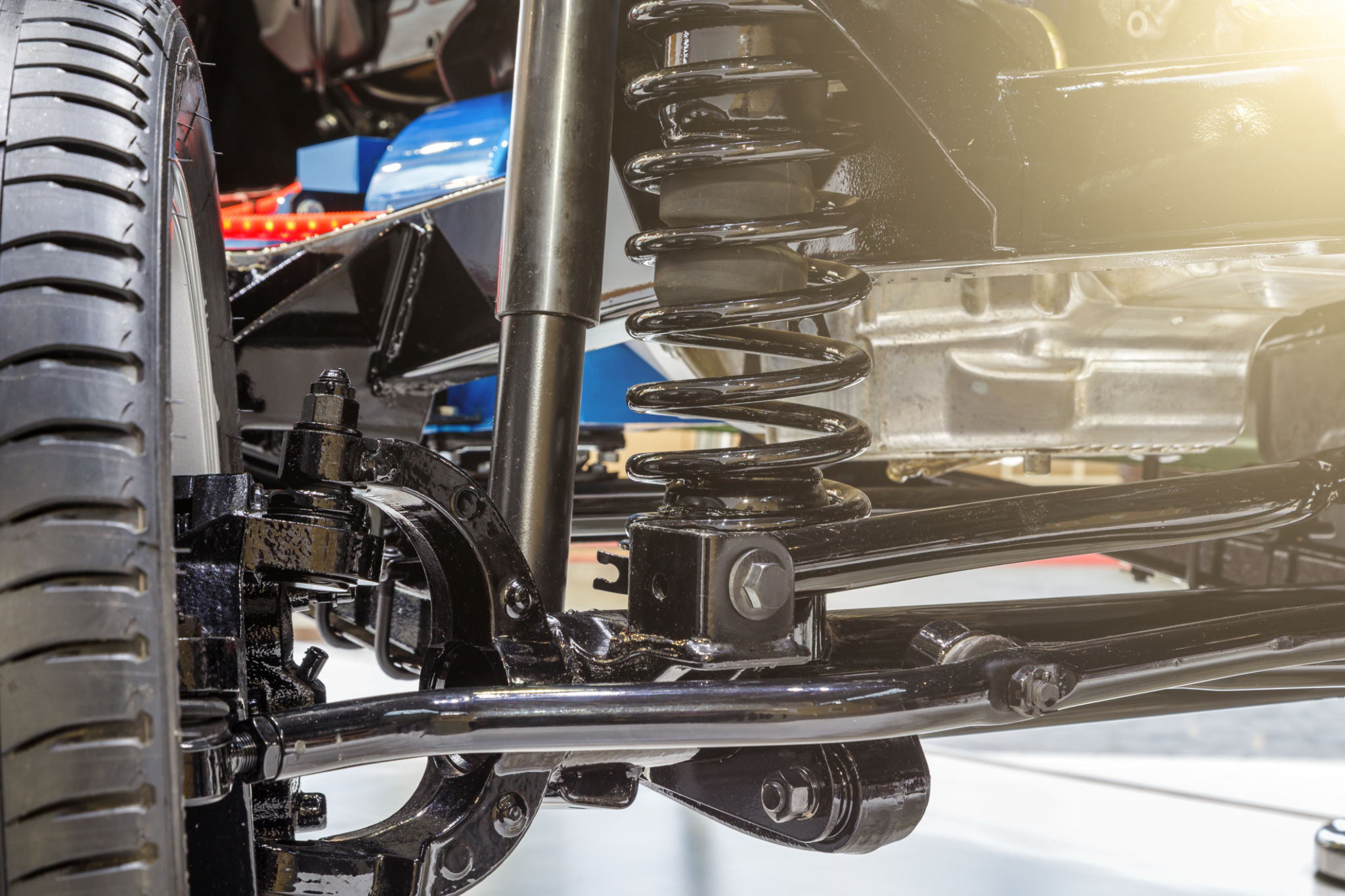

Inspecting the Suspension System

The suspension system is a vital component of your rock crawler. Regularly inspect the shocks, springs, and control arms for signs of wear or damage. Check for leaks in the shock absorbers and ensure that all bolts and nuts are tightened properly. An efficient suspension system not only provides a smooth ride but also enhances the vehicle's off-road capability.

Tire Care and Alignment

Tires are one of the most critical components of your rock crawler. Regularly check tire pressure to ensure optimal performance and safety. Inspect the tires for cuts, punctures, or uneven wear. Rotating the tires regularly can extend their lifespan and improve traction. Additionally, ensure that the wheels are properly aligned to avoid unnecessary strain on the suspension system.

Electrical System Maintenance

The electrical system in your rock crawler powers essential components such as lights, winches, and navigation devices. Regularly inspect the battery terminals and cables for corrosion or damage. Ensure all wiring is secure and free from wear. Consider using dielectric grease on connections to prevent moisture-related issues.

Brake System Checks

Brakes are crucial for safe off-roading. Regularly inspect brake pads, rotors, and lines for signs of wear or damage. If you notice any squealing or reduced braking performance, it may be time to replace the pads or other components. Bleed the brake lines periodically to maintain optimal braking efficiency.

Custom Modifications and Upgrades

If your rock crawler includes custom modifications or upgrades, these need regular attention too. Check custom bumpers, skid plates, and other add-ons for integrity and attachment. Ensure that any additional lights or winches are functioning correctly and securely attached.

Storage and Protection

When not in use, store your rock crawler in a dry, secure location to protect it from the elements. Consider using a high-quality cover to shield it from dust and moisture. Regularly starting the engine, even during storage, can prevent issues related to prolonged inactivity.

By following these DIY maintenance tips, you can keep your custom rock crawler in top condition, ready to tackle any off-road adventure. Regular care not only prolongs the life of your vehicle but also ensures safety and peak performance on challenging terrains.